Discrete Simulation Model Development for Enhancing the Efficiency of Seaweed Production Processes at PT. IHFIM

Main Article Content

Abstract

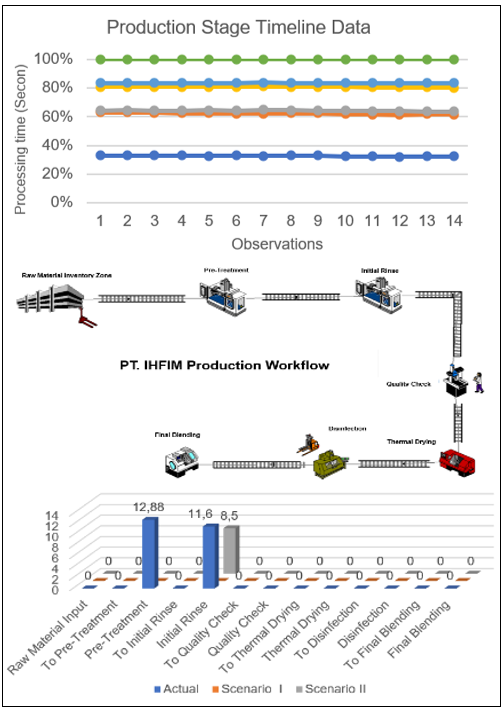

This study focuses on improving the efficiency of seaweed production at PT. IHFIM through the development of a discrete event simulation model. The production system includes several main stages such as Pre-Treatment, Initial Rinse, Quality Check, Thermal Drying, Disinfection, and Final Blending. Field observation and actual production data were used to build the simulation model using ProModel software. Model verification was done through running simulations, and validation was conducted statistically using a t-test, confirming that the simulation outputs were consistent with actual conditions. The analysis identified two bottlenecks in the system: Pre-Treatment with 12.88% blocked time and Initial Rinse with 11.60% blocked time. To address these issues, two improvement scenarios were tested. Scenario 1 added an extra tank to the Pre-Treatment stage, which successfully reduced the blockage to 0%. Scenario 2 introduced additional buffer capacity at the Initial Rinse and Quality Check stages, resulting in a 4% reduction in blockage. The results show that increasing capacity at key points can improve material flow and reduce delays. This study concludes that discrete simulation is an effective method for identifying bottlenecks and evaluating operational improvements in agro-industrial production systems

Downloads

Article Details

Section

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.