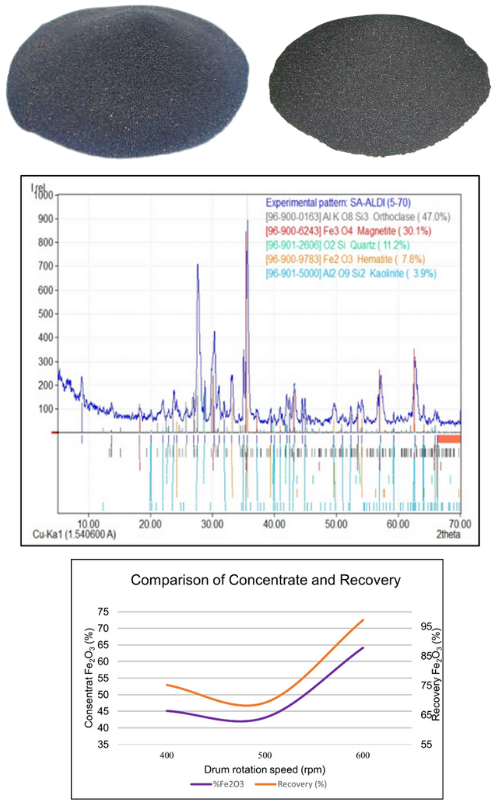

Effect of Drum Rotation Speed on Magnetic Separation Efficiency for Iron Grade Improvement of Galesong Beach Iron Sand Takalar Regency

Main Article Content

Abstract

Iron sand is a deposit along the coast formed from the weathering of rocks containing iron minerals, such as in Galesong Beach, Takalar, South Sulawesi. Its utilization is still minimal due to the lack of knowledge of its content and properties, so it is necessary to increase the content to obtain optimal recovery before being processed into useful products. This study aims to analyze the geochemistry of iron sand with XRF and XRD, determine the optimal recovery, and the best drum rotation speed on a magnetic separator for its processing. The method of increasing the content of iron sand uses magnetic concentration. The results of the XRD analysis show that the iron sand sample is composed of minerals such as Orthoclase (KALSi3O8), Magnetite (Fe3O4), Quartz (SiO2), Iron ore (Fe2O3), Kaolinite (Al2O9Si2). The results of the XRF analysis have Fe2O3 = 23.40%, SiO2 = 38.38%, Al2O3 = 25.92%, CaO = 7.16 %, TiO2 = 2.60 %, and K2O, MnO, V2O5, Cr2O3, ZrO, SrO, ZnO, P2O5 each below 1%. The iron ore (Fe2O3) content of the concentrate product at each drum rotation speed is 45.11 %, 43.06 % and 64.16 % with recovery values of 75.19 %, 69.18 % and 97.16 %. The percentage of Fe2O3 content and the most optimal recovery rate are obtained at a rotation speed of 600 rpm

Downloads

Article Details

Section

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.