Optimizing Banana Chips Production Planning in MSMEs Through the Goal Programming Approach

Main Article Content

Abstract

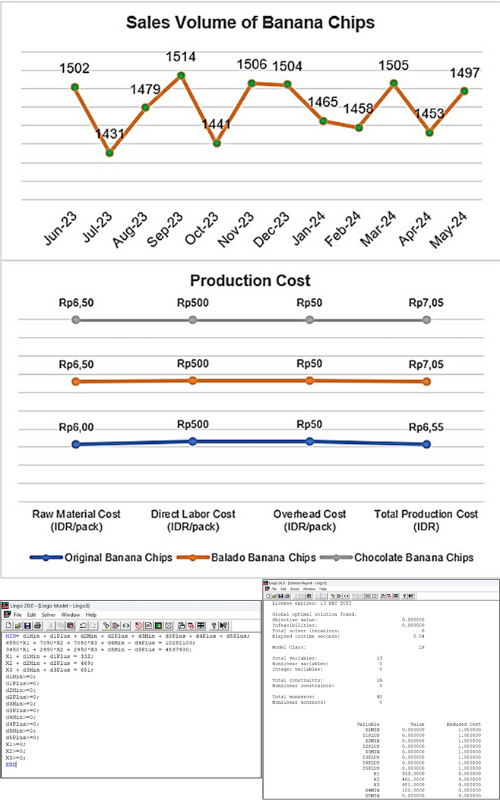

The UMKM Keripik Umi is a micro-scale enterprise that produces banana chips but currently lacks a structured and systematic production planning approach. Production decisions are still based on historical demand trends, leading to inefficiencies, especially when customer demand fluctuates. This study aims to optimize production quantities, minimize total production costs, and maximize sales revenue for three product variants: original, balado (spicy), and chocolate-flavored banana chips. To achieve these objectives, the Goal Programming method is utilized due to its effectiveness in solving multi-objective optimization problems, especially when there are conflicting goals. The results of the optimization show that the ideal production quantities are 4,191 packs for the original flavor, 8,187 packs for the balado flavor, and 5,434 packs for the chocolate flavor. With this production allocation, the minimum total production cost is achieved at IDR 123,479,100, while the maximum projected annual sales revenue reaches IDR 54,640,900. These findings demonstrate that the Goal Programming method can be a valuable decision-support tool for Micro, Small, and Medium Enterprises (MSMEs), particularly in managing limited resources while pursuing multiple business objectives. By implementing structured production planning using this method, MSMEs like Keripik Umi can significantly improve their operational efficiency, adapt more effectively to market dynamics, and enhance profitability in a competitive business environment

Downloads

Article Details

Section

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.