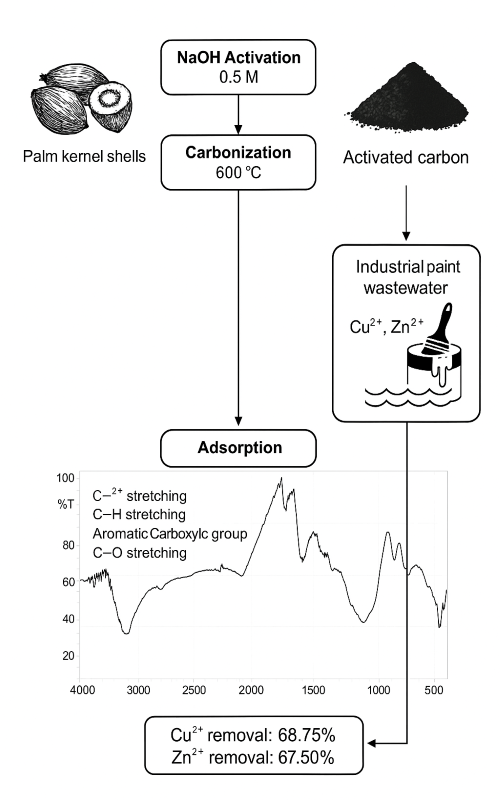

Sustainable Conversion of Palm Kernel Shells into Activated Carbon for the Removal of Cu²⁺ and Zn²⁺ from Industrial Paint Wastewater

Main Article Content

Abstract

Industrial paint effluents are major contributors to aquatic heavy metal contamination, creating serious environmental and public health concerns. Conventional treatment methods are often costly and unsustainable, underscoring the need for renewable and effective alternatives. In this study, palm kernel shells (PKS), an abundant agricultural byproduct, were valorized into activated carbon (PKS-AC) for the removal of Cu²⁺ and Zn²⁺ ions from real paint effluent. The adsorbent was prepared through chemical activation and high-temperature carbonization, yielding a material with high fixed carbon content (69.2%) and reduced volatile matter (14.0%), which provided structural stability and enhanced adsorption sites. Batch adsorption experiments revealed optimal conditions at pH 7, 90 minutes, 2.0 g/L dosage, and 55 °C, achieving removal efficiencies of 68.75% (Cu²⁺) and 67.50% (Zn²⁺). Kinetic modeling followed the pseudo-second-order model, suggesting chemisorption, while thermodynamic analysis confirmed the process to be spontaneous and endothermic. Importantly, regeneration tests showed PKS-AC retained strong performance over multiple cycles, highlighting its reusability. The novelty of this work lies in demonstrating the efficacy of PKS-derived activated carbon for treating real industrial paint wastewater, rather than synthetic solutions, while providing a complete evaluation of adsorption performance, kinetics, thermodynamics, and reusability. These findings establish PKS-AC as a sustainable, cost-effective, and circular-economy-driven adsorbent for large-scale wastewater treatment.

Downloads

Article Details

Section

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.